Products

Products DETAILS

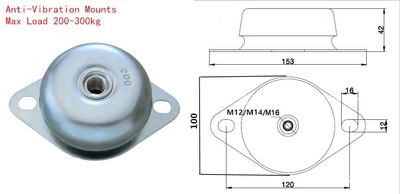

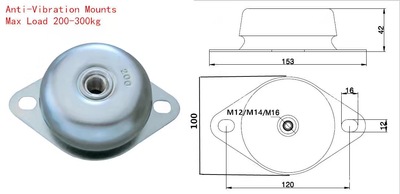

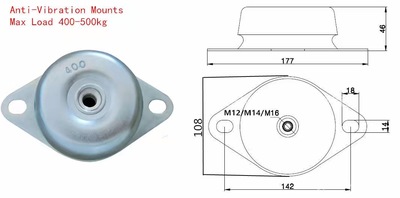

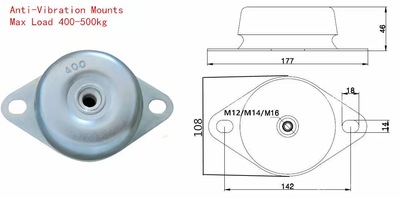

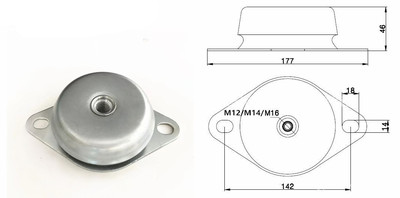

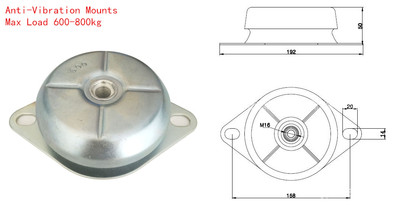

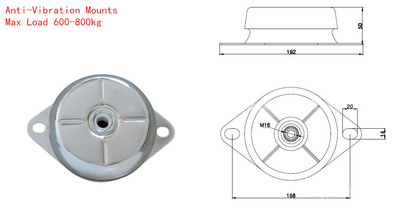

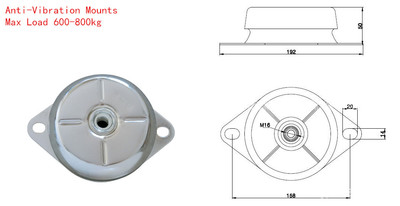

Vibration Dampers

PRODUCT APPLICATION

Vibration isolation of mobile rotating machinery subjected to axial and radial impacts,

Generators, air compressors, fans, motors, centrifuge pumps, industrial and mining machinery, etc.

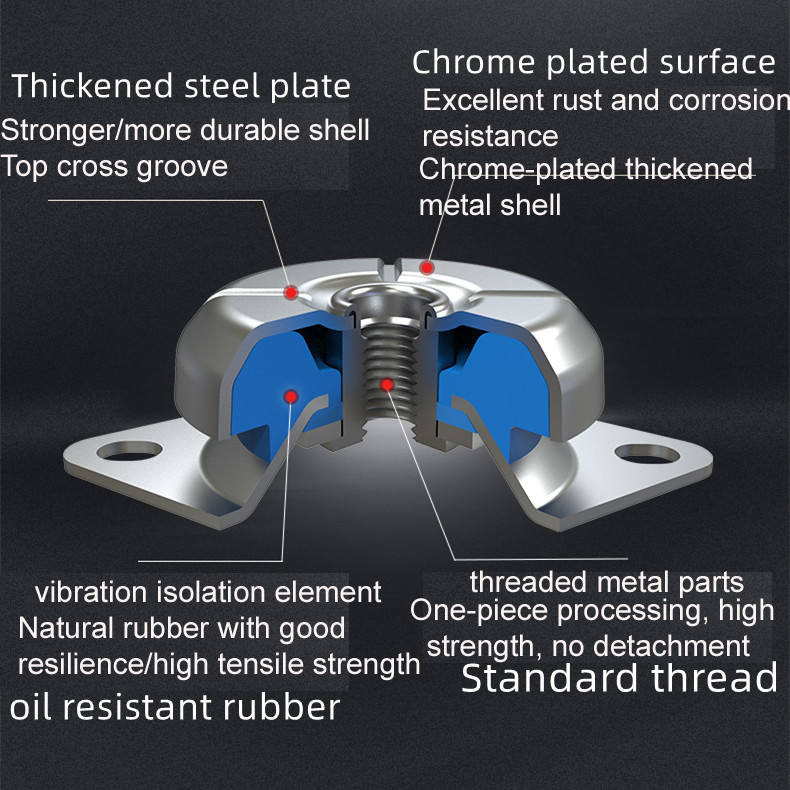

PRODUCT CHARCATERISTICS OF SHOCK PAD

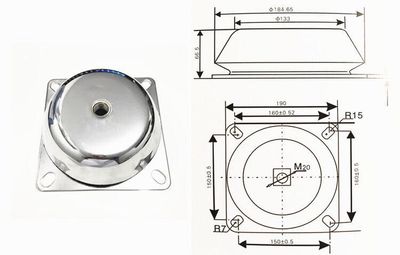

1. The damping pad adopts a bell-shaped design, which has strong stability, large bearing capacity and long service life.

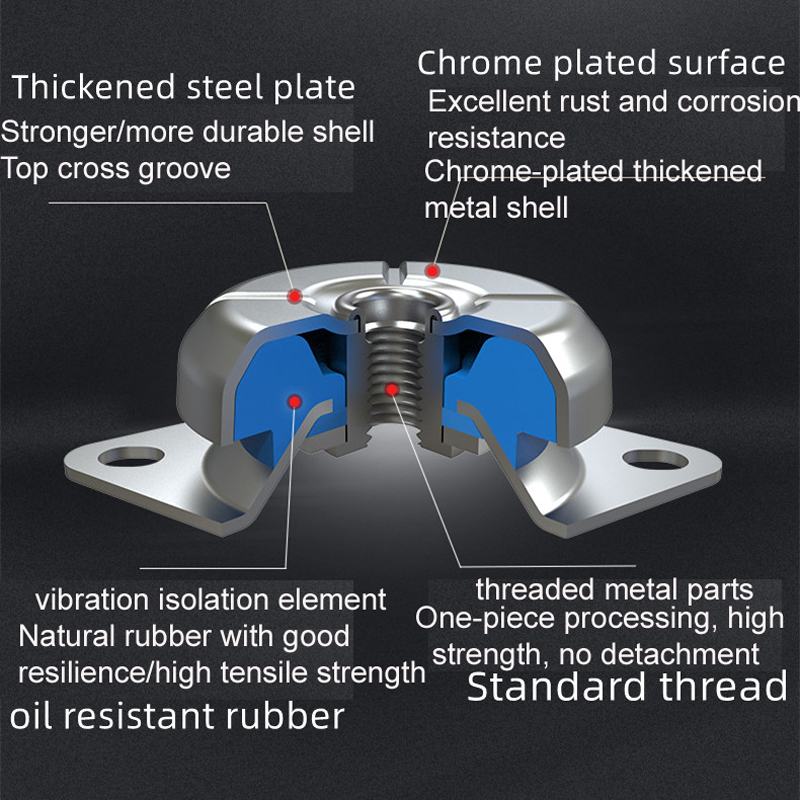

2. The internal rubber and metal are perfectly glued to provide the most efficient shock absorption effect.

3. lt can bear axial and radial forces at the same time, and the axial elasticity is greater than

the radial elasticity, which can not only compress and shear but also prevent accidental overload impact.

4.The exterior adopts chromium plating process, and the interior adopts newly made

styrene-butadiene and nitrile rubber. The main features are: oil resistance, oxidation resistance, aging resistance, heat resistance, abrasion resistance, ozone resistance, corrosion resistance,

good elasticity, and can prevent objects from corrosion of the components, which makes this series of products more conducive to outdoor use, and enhances the ability of the shock absorber to adapt to external factors such as weather.

5. This product comes with metal safety locks and comes with a stop loss device to ensure safe and stable use.

6. There is a cross punch groove on the top of this product, which not only enhances the rigidity, but also facilitates the discharge of oil or liquid deposited in it.

RUBBER CHARACTERISTICS

Characteristics of SBR

1. The rubber material is not easy to burn and oversulfur, and the vulcanization flatness is good.

2. Wear resistance, heat resistance, oil resistance and aging resistance are better than natural rubber.

3. During processing, the molecular weight will not decrease after it drops to a certain level, so it is not easy to over-refining and the plasticity is uniform.

4. Increase the molecular weight to achieve high filling. Oil-extended styrene butadiene rubber has good processing properties.

5. lt is easy to use with other unsaturated general-purpose rubbers, especially with natural rubber and butadiene rubber. The shortcomings of styrene butadiene rubber can be overcome by formula adjustment.

Characteristics of nitrile rubber

Nitrile rubber is produced by emulsion polymerization of butadiene and acrylonitrile. Nitrile rubber is mainly produced by low-temperature emulsion polymerization. With the characteristics of styrene butadiene rubber, it has excellent oil resistance and strong adhesion.

HOW TO CHOOSE SUITABLE SHOCK PAD

THE FIRST

Engine weight +generator weight, divided by the total number of installation angles, and

then multiplied by the safety factor 1.6. Finally, the corresponding type of shock-absorbing pad is selected.

For example: the weight of the engine is 2000Kg, the weight of the engine is 2000kg, the number of supporting angles for the engine is 6, and the number of supporting angles for the generator is 4.

Calculated as follows:

(2000+2000)÷(6+4)*1.6=640kg, optional 700kg or 800kg shock cushion.

THE SECOND

The weight of the engine is divided by the number of mounting angles, and then multiplied by a safety factor of 1.6, and finally the corresponding type of shock-absorbing pad is selected.

In the same way, the weight of the generator is divided by the number of installation angles, and then multiplied by the safety factor 1.6, and finally the corresponding type of shock-absorbing pad is selected.

For example: the weight of the engine is 1200kg, the number of installation angles is 4, that is, 1200÷4*1.6=480kg, and 500kg or 600kg cushions are optional.

In the same way, for example: the weight of the matching generator is 600kg, the number of installation angles is 2, that is 600÷2*1.6=480kg, 500kg or 600kg damping pad is optional.