Products

Products DETAILS

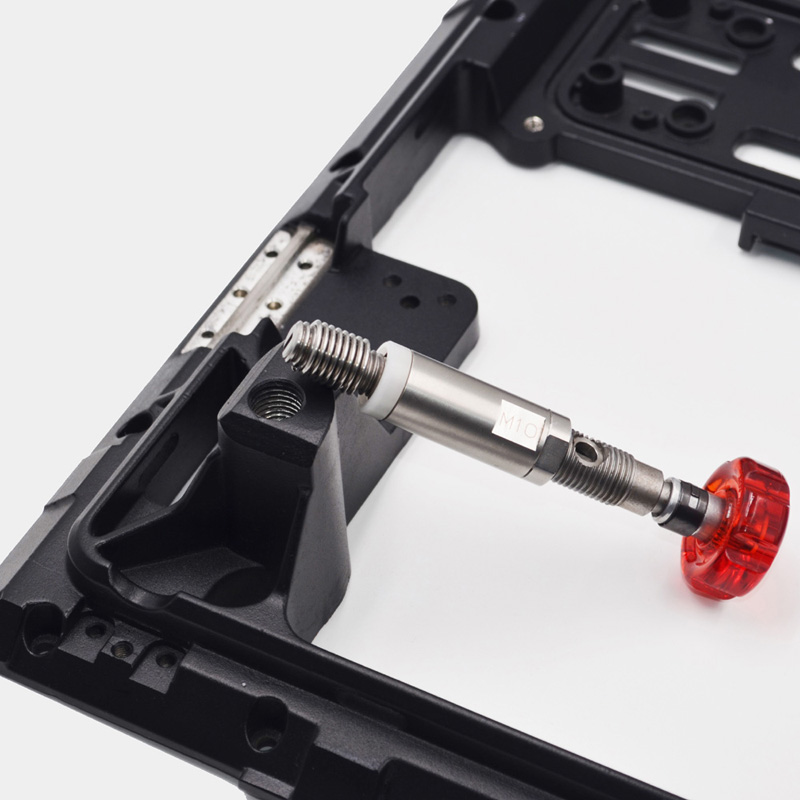

Tangless Threaded Inserts

Product Description

Thread inserts are formed from high quality stainless steel wire with a diamond shaped cross section, wound to the shape of a spring thread. Once the wire is wound into a helical coil and installed into a tapped hole, it provides a permanent and wear resistant thread in the parent material that is generally stronger than the original thread. The thread inserts are designed to be greater in diameter than the tapped hole and compress as they are installed. This allows maximum surface contact area with the tapped thread, safely and permanently anchoring the inserts into place. The insert's compensatory action shares the load over the entire bolt and hole, increasing pull out and torque out strength. With a thread insert in place, load and stress are more evenly distributed over the assembly.

Thread inserts: Where to use?

Original equipment manufacturer

Thread insert offers innotive way for manufactuer to design and produce high quality products using lighter materials such as

aluminium die casting and magnesium alloy parts. While can still achieve high strength and reliability in assembly.

It is widely used in manufacture of following industries:

1. Aerospace and defense

2. Ship building industry, high speed train and other transportation

3. Automotive industry especially new energy automotive

4. Industrial and consumer electronics

5. High precision industrial parts

6. Aluminium die casting and magnesium alloy parts

Thread repairing

Thread insert is a ideal and simplest way for repairing stripped or damage threads.

Tangless Inserts are wire thread insert without a tang. Same as standard thread insert, it provides all of

the strength and easy installation characteristics, but with a big advantage: no tang to break off after installation.

Advantages:

1. No tang to break off after insert installation. Ideal for automatic installation in high volume applications.

2.No tang to retrieve after installation, eliminating the requirement for vacuuming or extraction.

3. Bi-directional design eliminates inert orientation. Eliminate the need for time-consuming insert checking prior to each installation.

4. Tangless insert saves time in your insert installation work.

(Metric sizes or UN sizes series to be provided on request)